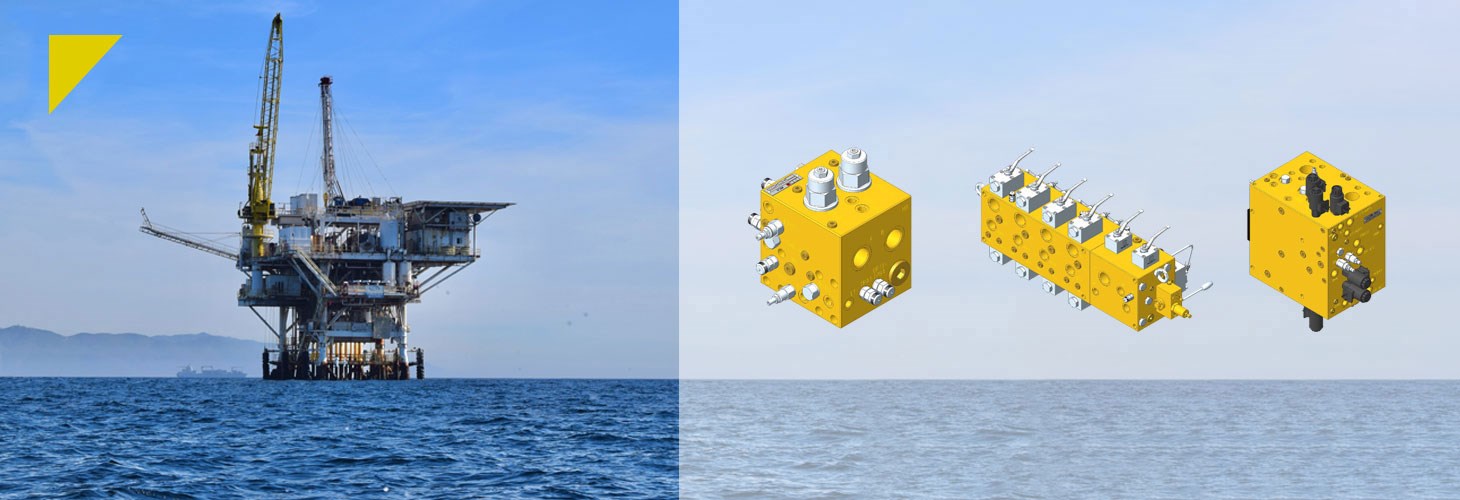

Custom valve blocks and manifolds

For our specially designed valve blocks, we choose the best from our own production and our suppliers together with the customer. We deliver hydraulic blocks and manifolds for maritime, industrial, mobile, and offshore applications.

Contact us about custom valve blocks

Ever since Hydranor was established in 1962, we have delivered robust and reliable hydraulic blocks and manifolds for demanding applications.

For our hydraulic blocks and manifolds, we use components according to customer requirements and specifications – typically components from:

- SUN Hydraulics

- HAWE

- ATOS

- MOOG

- BUCHER

Advantages of our hydraulic valves and manifolds:

Servi offers a safer and more environmentally friendly solution:

- Compact Design: We design all our hydraulic blocks and manifolds in 3D and optimize size/weight and cost.

- Safer System: On our valve blocks, all pipe connections have been removed. This simplifies assembly and reduces leakage points.

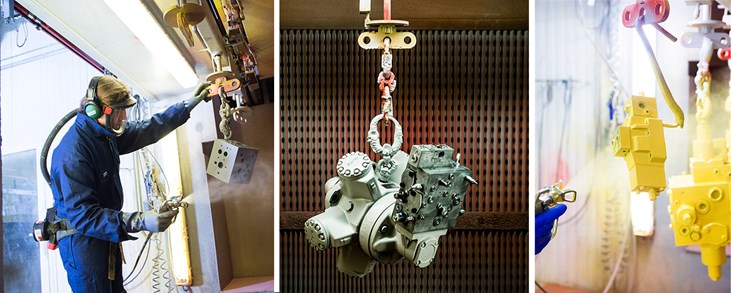

- Tested Before Delivery: We pressure and function test all hydraulic blocks and manifolds according to the specifications agreed upon at the time of order.

- Easy Troubleshooting: All ports and components on our hydraulic blocks and manifolds are easily identifiable with engraved marking – this, along with comprehensive drawing documentation, makes operation follow-up and troubleshooting easy for service personnel.

Painting and testing

At our factory in Kongsberg, we carry out a wide range of surface treatments, including painting. Painting is important to enhance durability. The paint on the corners of hydraulic blocks tends to wear out quickly, so our blocks have rounded corners to prevent rust from forming. Two layers of component primer are applied before a top colour (of the customer’s choice) is added.

Higher valve performance with digitisation

All of our hydraulic products can in adition to hydraulic remote control be delivered with:

- Open loop electric remote control

- Closed loop digital remote control

We use Servi’s own developed valve technologyresulting in higher accuracy, repeatability, responsiveness, and performance.

Read more about SAC on servi.no

Watch the webinar: Servi valve/block production in Kongsberg

Contact the factory in Kongsberg