Offshore wind

Over 100 years of experience in delivering power and motion control to the marine and offshore industry, makes us a valuable partner for all phases of offshore wind projects; everything from concept to operations and maintenance.

Offshore wind – project from start to finish

Servi delivers within the following phases:

1. Concept development

2. Engineering

3. Installation

4. Service and maintenance

The illustration shows a simplified version of the value chain in offshore wind. Servi can deliver solutions within the blue areas.

Your advisor in concept development and engineering

Servi has a skilled technical department with innovative and highly experienced engineers. Our knowledge of hydraulics, control systems, electrical equipment mechanical design and documentation, allows Servi to deliver turnkey solutions. The use of advanced design and simulation tools is essential in ensuring optimal solutions.

We use the following design tools

SimulationX is based on credible simulation results, enabling you to predict the dynamic behavior of a system and optimize the design process. This provides important savings when starting up new systems. Source: Simulation in the software SimulationX, (C) ESI Group 2022

Offshore wind projects

We have done the project management required in offshore wind countless times before. The process of requirements, specifications, documentation and project management is very similar in offshore wind, marine and oil and gas. This makes us well equipped to assist offshore wind projects.

Servi is a complete supplier of hydraulics and control systems. We deliver high quality products from well-known suppliers around the world. Typical product deliveries, which we deliver to offshore wind:

Motion compensated gangways

Servi delivers hydraulic systems to standalone gangways. This includes HPU, (hydraulic power unit), valve cabin, valve block, accumulator, gas tank, hydraulic cylinder with motors and plain bearings. The gangways are called Walk to Work (W2W) system, as they are being used for person and goods transport between ships and offshore installations. One of Servi Group’s key customers in this area is Uptime International, which delivers logistics solutions for the entire offshore energy sector and has 40 years of experience with gangway deliveries.

Uptime has been using Servi since 2012 on our motion compensated gangways. These have proven to be highly reliable systems. In addition, Servi is very service minded if challenges arise. When designing our new autonomous system, we had no doubt who to use.

Anders Grindheim, Discipline lead – Hydraulics & Mechanical, Uptime

Cylinder and accumulator systems

We have solid and long experience in supplying cylinder and accumulator systems for many years, such as shock absorbers. These systems ensure handling of heavy lifting between ship and installation.

Cranemaster has been one of our customers for many years in cylinder and accumulator systems. The images above show one of many deliveries of the shock absorbers from Servi to Cranemaster.

Pile gripper

A pile gripper effectively lifts the monopile foundations from ships to the final position in the ocean. In order for the monopile foundation to be safely and securely lifted, the Pile gripper is motion compensated. This means that it steadily dampens wave forces at lowering, while maintaining an accurate vertical position.

Servi supplies cylinders, valve blocks, sliding bearings and link arms to Pile grippers. These components are critical to Pile gripper's precise execution. Link arms help keep the position of the monopile foundations in place, regardless of diameters, before the Pile Gripper takes over the positioning.

System deliveries

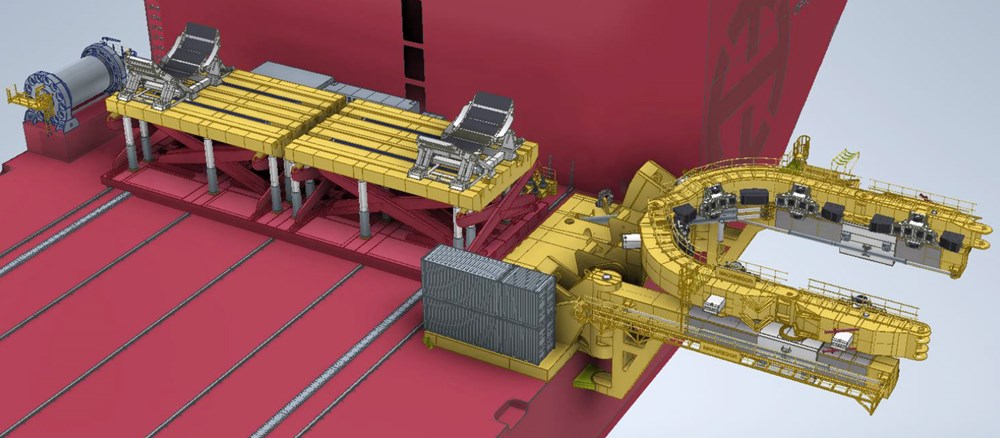

Installation systems for wind turbines

Installation systems for wind turbines

We have delivered a number of systems, which contain advanced hydraulics in combination with sensors and electrical control systems. Some typical deliveries are:

- Stewart platforms with dynamic movement in 3 dimensions

- Heave-compensated systems that measure wave movements and adjust winches or platforms to the correct position

- Installation systems for wind turbines

Maintenance- free sliding bearings at sea - fairleads

Servi has safe and maintenance-free anchoring of underwater installations for floating offshore wind and marine fairleads.

We have more than 75 years of experience in tribology and high technical expertise. Self-lubricating, maintenance- free plain bearings have many advantages in several applications because of its low coefficient of friction and good ability to handle shock loads and edge forces. We can assist you to find the best solution in bearings to achieve best possible lifetime and reliability.

Read more about GGB Plain Bearings

Service and maintenance

Servi takes responsibility for the maintenance, which includes inspection and status testing based on operating patterns and environment. This maximizes uptime and prolong service lifetime. With more than 50 service engineers, spread over 7 locations, we can provide most locations with the right certificates.

Read more about our Service maintenance