Hydropower – power and motion control

Servi has over 110 years of solid expertise in power and motion control. We help our customers think outside the box and deliver innovative and energy-efficient solutions.

We offer everything from standard components and systems to customer-specific solutions. In addition, we offer tailor-made service agreements to suit your facility and needs.

Our deliveries

Comprehensive solution between existing and new equipment

Do you need to upgrade your existing facility, or do you need a brand new one?

Did you know that Servi Group has delivered over 600 hydraulic systems to hydropower since the late 70s?

We can deliver everything from simple standard systems to customer-specified systems, where we take total responsibility for system solution, design, assembly, test installation, start-up and final documentation.

It is always your need that comes first, then we tailor the best solution for you. We do this by, among other things, looking at which systems and components work best together.

In addition, we can take responsibility for service and maintenance – so you extend the lifecycle of your components and systems.

Looking for documentation and drawings from previously performed work? We have taken care of most things.

Although we have not always been called Servi Group, we have been around since 1912 and had several names; among other things: PMC Group, Servi Motion Control, Sjong Hydraulikk, Vickers, Venditor, Servi Hydraulikk, Hydratek, Servi Technic, Servi Cylinderservice, Hydranor, Hydronic, and Ingeniørforetningen Atlas.

Service and maintenance agreements

We can offer tailor-made agreements that can be adapted to each facility. The inspection agreement gives the user of the plant a predictable operating cost.

Typical service deliveries to hydropower plants are:

- Condition monitoring (survey at the plant)

- Recommended rectification of deficiencies

- Upgrading the facility

- Accumulator check

- Sale of spare parts

Oil samples in combination with a condition report will give a warning if something should be rectified before it goes as far as plant downtime. An inspection agreement can be carried out at new and old facilities.

Total delivery of upgrades of existing facilities for Statkraft Suldal Dam:

-With the work at Osvad, Servi has delivered good work and taken challenges in stride. The result has been very good, with an orderly installation and satisfactory function on the pull-up.

Helge Steinbru Lauvsnes, Statkraft Suldal dam

Quick cylinder rod replacement resulted in minimal downtime

- Servi sat on the old original drawings (back then it was Servi Cylinderservice) and during the summer holidays was able to make a new cylinder rod after these drawings. The access to the original drawings meant that we had minimal downtime on the hatch – if we had not had these, we could easily have seen one month of downtime.

Geir Åsbjørn Ovedal , VTA i Sira Kvina Kraftselskap

Noen av våre leveranser er levert til:

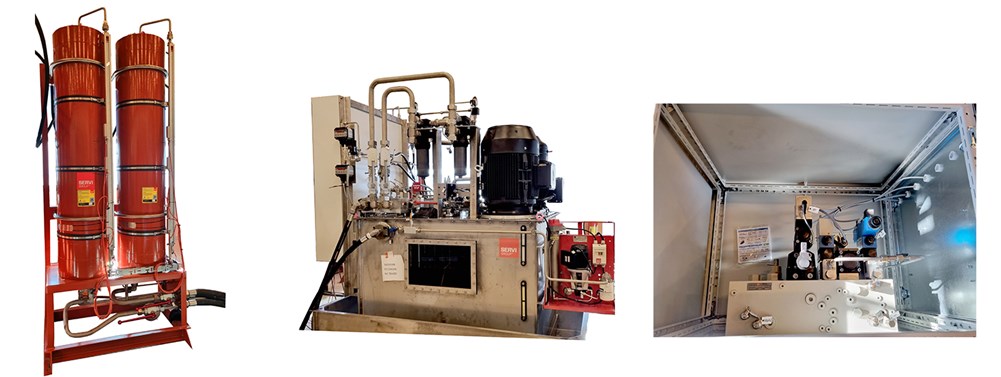

Example hydraulic delivery to hydropower:

From the left: Piston accumulator 2x 200 liter, Hydraulic power unit to pelton turbine and servo block for motion control of neadle to pelton turbine.