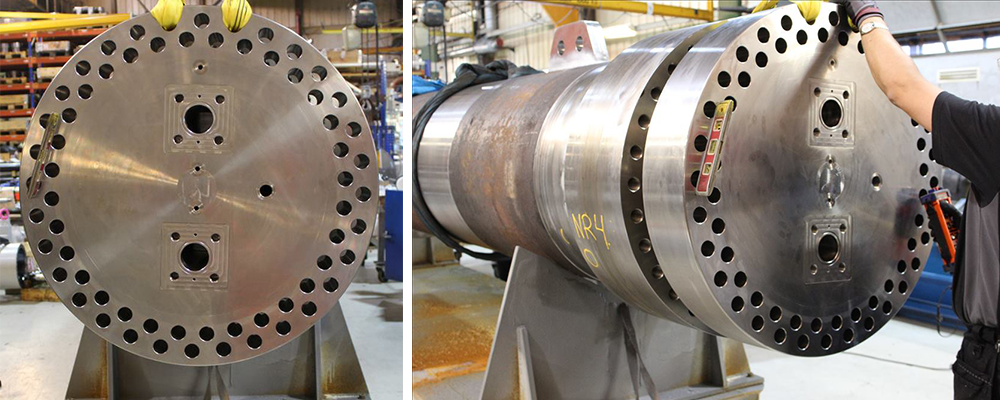

Servi is the largest manufacturer of accumulators in Norway. We design and manufacture accumulators in a range of materials and in accordance with customer-specified needs, and accessories, such as end switches, rupture discs and internal and external position sensors.

We develop and manufacture accumulators tailored to your specifications, pressure ranges and operating conditions.

.

Choose from several accumulators in our product catalogue.

Servi offers service and reclassification on all types and makes – in the workshop or out in the field.